Solar That Can Stand up to ‘Climate Whiplash’

As the world heats, evidence suggests we will experience more volatility between weather extremes. Researchers have termed the effect "Climate Whiplash", and believe it likely has roots in the warming arctic and climate change.1 https://e360.yale.edu/features/climate-whiplash-wild-swings-in-extreme-weather-are-on-the-rise This could mean an increase in extreme swings between freezes and thaws – and with it, a need for more reliable solar panels. Not all solar performs the same in wild temperature swings and humidity. A poorly performing system will limit your sustainability and financial return.

Across 35 years and more than 30 million panels, Maxeon Solar Technologies industry-leading R&D investment2 Based on cumulative investment from 2007 through 2018. Osborne. " R&D spending analysis of 21 PV manufacturers." PVTech.com 2019. has toughened our solar technology to perform in harsh conditions. Our flagship Maxeon panels maintain their power 2-3x better than conventional panels3 Jordan, et. al. Robust PV Degradation Methodology and Application. PVSC 2018. , and are backed by one of solar's strongest warranties.4 Based on Jan, 2019 review of warranties on manufacturer websites for top 20 manufacturers per IHS 2018. Our Maxeon line panels also have a low return warranty rate of only 0.005%, as measured across more than 15 million panels.5 "A Comparative Study: SunPower DC Solar Module Warranty Claim Rate vs. Conventional Panels." SunPower Corporation. 2019.

Workers place the finishing touches on our flagship Maxeon panels.

Designing for Reliability

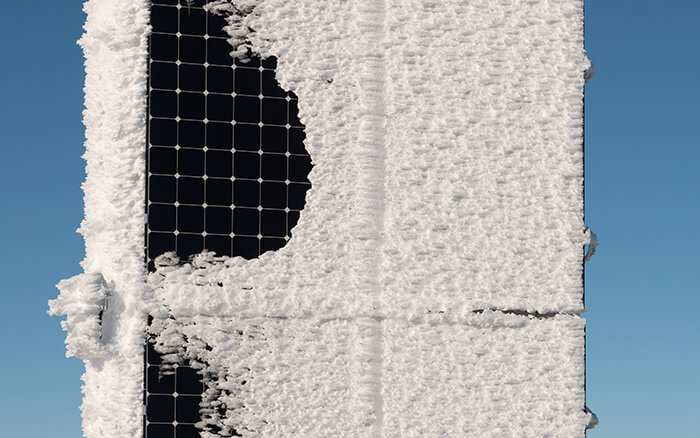

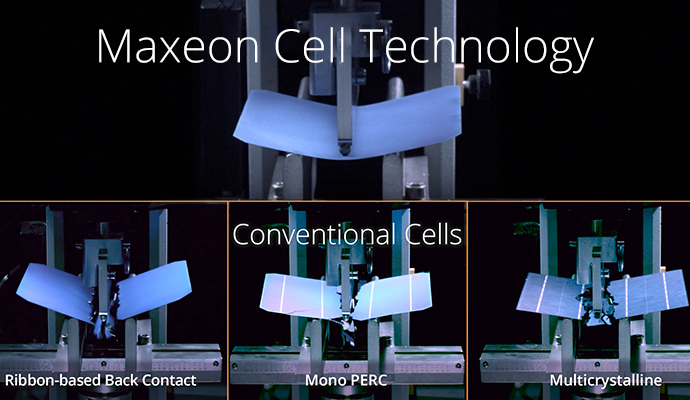

When temperatures swing from very cold to very hot, the metal cells and ribbons within solar panels contract and expand at different rates. Over time, this can result in breakage for cells without a solid metal foundation. The patented solid copper foundation of our Maxeon cells allows it to bend under tough conditions where others break.

This effect is compounded if rain, snow or coastal air allows moisture to enter the solar panel at temperatures above freezing. This water can then freeze at the cold part of the cycle. The resulting ice expands and can damage the surrounding area.

This is very much like when roads thaw and freeze. At temperatures above freezing, moisture will make its way into any small crack in the pavement. Then, when temperatures drop, the water begins to freeze and expand from within the cracked pavement, magnifying the crack. Water expands by 10% when frozen, and can exert over 30,000 psi as it expands. In short, whether we're talking about roads or solar panels, there is no stopping frozen water from inflicting damage from the inside out. Then, when warming weather melts the ice again, the cycle of damage begins anew.

The same mechanism that destroys roads during the winter also induces power loss in inferior solar panels.

In addition to protecting against breakage, the Maxeon cell’s tin-plated copper foundation protects against corrosion, which can cause the degradation and failure of Conventional Panels.

Maxeon Solar Technologies has also designed its panels without the use of EVA encapsulant, an ingredient found in more than 90% of solar panels.6 International Technology Roadmap for Photovoltaic (ITRPV) – March 2019. Research has demonstrated that EVA-based modules are vulnerable to physical stress at low temperatures7 Effect of Encapsulation Modulus on the Response of PV Modules to Mechanical Stress, Rafal Mickiewicz et al, Fraunhofer Center for Sustainable Energy Systems. , since the EVA becomes stiff, passing stress onto the underlying cells. A brittle encapsulant with brittle cells is more likely to incur cracking than Maxeon's robust design which can flex and remains electrically connected, even if cracking occurs.

We Test Inside and Out

We qualify our flagship Maxeon panels through a brutal test called Humidity Freeze that mimics the whiplash of a freeze-thaw cycle. The test involves a temperature swing of -40 to +85°C, 5 cycles per day, with high humidity soak (85% RH) at the top part of the cycle.

Technicians load a Maxeon panel into a laboratory testing chamber.

Testing reveals that there is almost no impact from this stress on Maxeon panels, even after 380 cycles (38 times what's required for certification). Conventional panels, on the other hand, show power loss after 10 to 20 cycles.

Extreme weather patterns might be the new normal. But Maxeon Solar Technologies is committed to the continued innovation of our technology. Just as our customers stand up to climate change, our panels will stand up to harsh conditions. Together, we can make a difference in the fight against a warming planet.